Materials Processing Research

Making Nanostructured Alloys Stronger Yet Malleable

What’s Involved in this Research?

This project is designed to develop a better understanding of impact-mediated deformation and to allow scalable manufacturing methods.

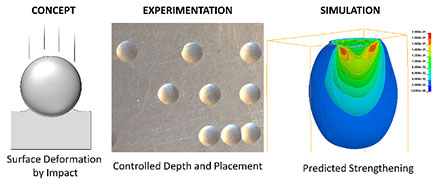

This will be accomplished using a technique called surface mechanical attrition treatment (SMAT), where a surface is repeatedly impacted to strengthen it. By carefully controlling the placement of impacts and the impact energy, the strength and deformation can be more accurately correlated. This will allow the process to be quantified.

Surface mechanical attrition treatment (SMAT) process

Furthermore, the methods being used are readily applied using current manufacturing technology. With these advancements, it is expected that metals and alloys can be fine-tuned to maximize strength without making them brittle.

Lighter, more fuel-efficient transportation, longer lasting orthopedic implants, and safer structures of all types can be benefitted by new metals and alloys (a mixture of metals).

Metals can be made stronger by deforming them during processing, a practice that has been used for many years. The challenge with these strain-hardened materials is that the stronger they get, the more brittle they become. Newer methods that “severely” deform metals have made them even stronger by refining their structure until it has nanometer size features.

Despite their potential advantages, these nanostructured alloys are not easily applied to create useful components, and they are still too brittle for many uses.

To balance strength and brittleness, the structure of the metal may be only partially nanostructured so that the other areas with coarser structures can allow it to deform without breaking. This strategy has shown promise in recent years, but there is still limited control, and most methods are not readily converted to large-scale commercial production.

How Students Benefit

Engineering is an applied science, and there is no substitute for experience. Research provides opportunities to use and expand coursework topics, and it presents open-ended questions and requires innovative solutions within given constraints. These skills will be valuable in any career later on. Their coursework gives them the tools. Research develops their ability to use those tools.

Students are involved at all levels. Undergraduates perform experiments, they measure, image, and otherwise characterize the resulting properties, they assist in writing scientific articles, and they present at conferences. Graduate students are involved in these same activities, but they are expected to have more of an independent role and consider new directions for research. They will often have greater laboratory management responsibilities and mentor undergraduates as well.

Research Professor

Dr. Mark Atwater

B.S., M.S., Ph.D.

Professor of Mechanical Engineering

Google Scholar Profile

Impact on Society

Advanced materials enable other technologies to develop. Better materials provide greater versatility in how we construct everything from circuits to surgical tools. The common denominator in every engineering discipline is the need to work with materials directly or indirectly. Advances in materials are the foundation for inventions that make our lives easier, safer, and otherwise more enjoyable. This project may help develop stronger and more reliable components to reduce weight, increase performance, and improve lifetime.