Search News Archives

Filter News Articles

Additional Navigation

New high-tech microscope gives School of Engineering, LUCOM competitive edge in research

July 8, 2022 : By Ted Allen - Office of Communications & Public Engagement

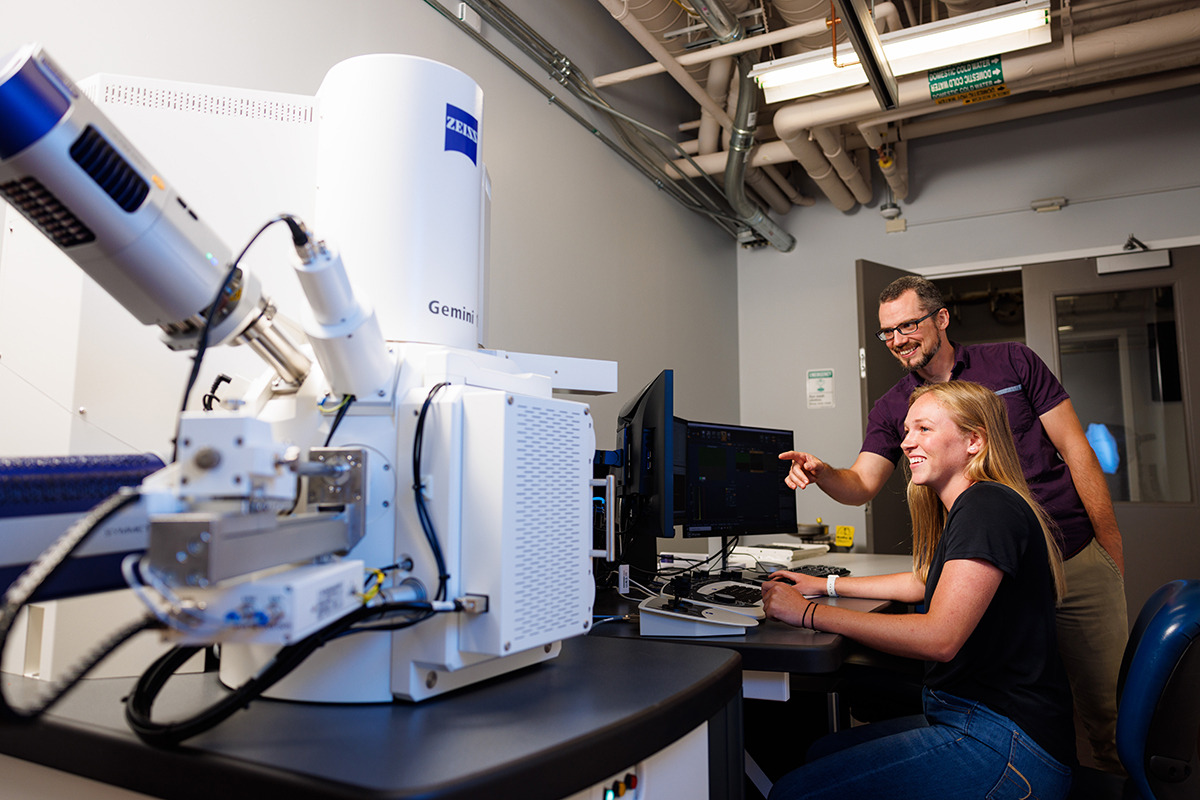

Liberty University’s School of Engineering (LUSE) recently installed a Field Emission Gun (FEG) Scanning Electron Microscope (SEM) that will be one of the most versatile of its kind in laboratories and research institutions throughout North America.

The device, manufactured by the German company Zeiss and currently housed at Liberty’s Center for Engineering Research & Education (CERE), will prove invaluable in expanding research options for undergraduate and graduate students in various departments.

It provides 10-20 times greater resolution and more powerful magnification capability than the school’s previous microscopes and is much more functional in analyzing and manipulating samples.

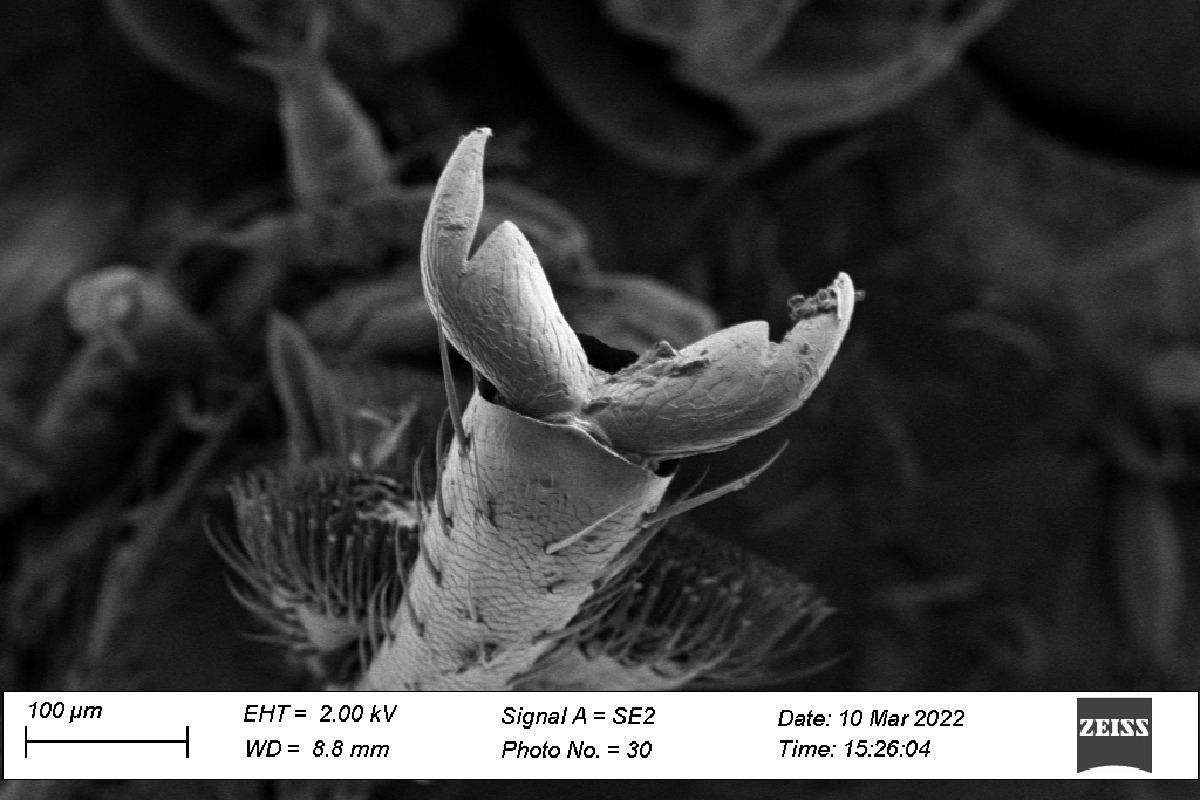

“It does regular optics all the way down to nanometer (1 billionth of a meter) scale, down to 2 million X (magnification),” said School of Engineering Senior Lab Manager Stephen Horstemeyer, who has used the microscope to view yet-to-be-named nanofossils.

The SEM can also be used as a Scanning Transmission Electron Microscope (STEM), which also allow for analysis of samples that are so thin that they appear transparent.

Dr. Mark Atwater, an associate professor of mechanical engineering who specializes in material sciences, said the machine is a game-changer for LUSE, the Liberty University College of Osteopathic Medicine (LUCOM), the School of Health Sciences, and other departments.

“This is something that’s unique to the Central Virginia region,” Atwater said. “Nobody within an hour’s drive has anything like it, and even some of the state colleges won’t have this kind of capability. We are also hoping that it will be more user-friendly for outside companies to come and use it.”

“It will make for a more meaningful experience for our undergraduates to use in their courses, and it will be very valuable for our graduate students to do independent research and to sort of push the frontier in materials science,” he added.

The microscope is located in a sound- and vibration-insulated room across the hallway from LUCOM’s Arcam EBM Spectra H, an industrial 3D printer that uses computer-aided design to produce complex metal parts via electron beam melting.

“That is also something unique to us, so we’re trying to have a sort of menagerie of value-added equipment here so that other people will come for one aspect, see the others, and then become users and collaborators,” Atwater said.

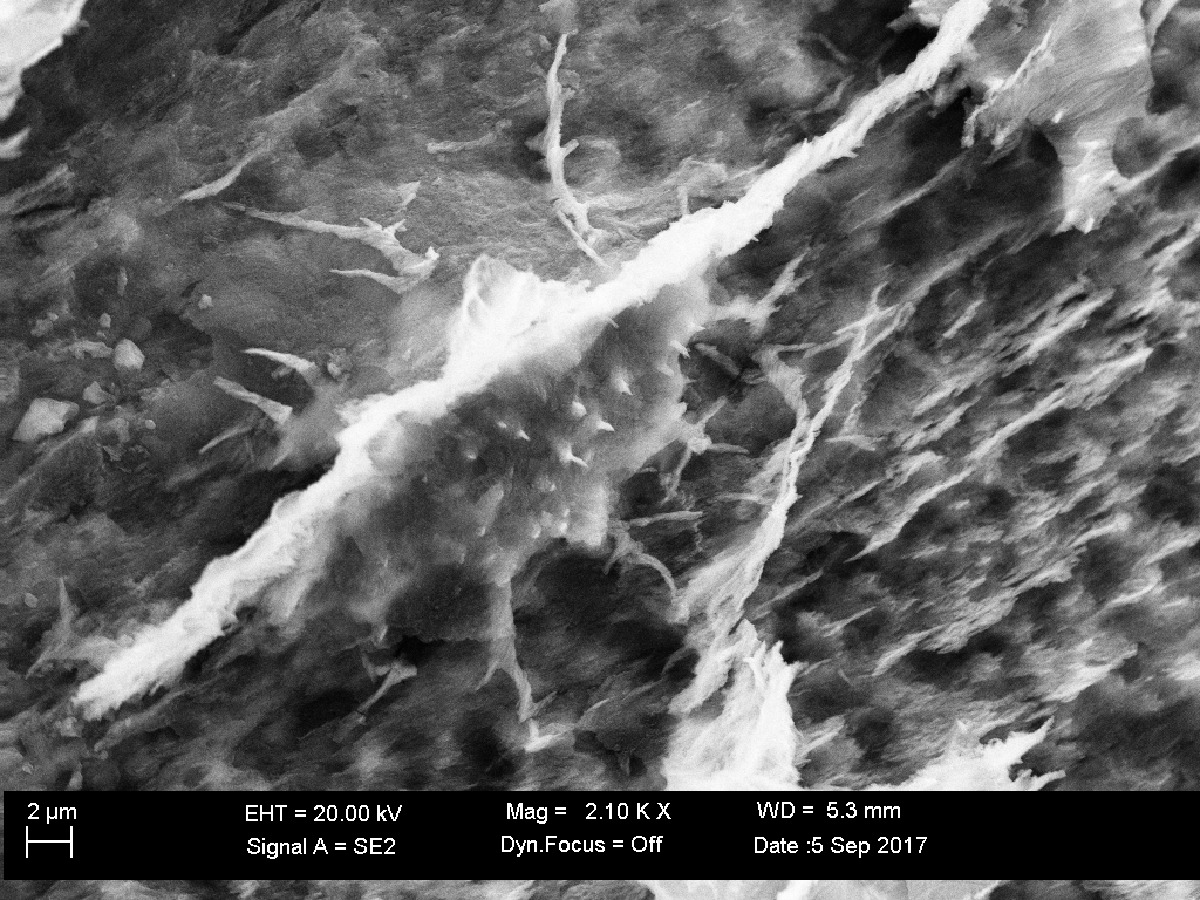

The microscope features Electron Backscatter Diffraction (EBSD), which indicates the grain orientation of the metal or substance being studied, and was recently equipped with an Energy Dispersive Spectrocity (EDS) detector for chemistry analysis.

“The EDS allows it to be a tool to get your elemental information, to tell the chemistry data and composition of (the matter),” Horstemeyer said.

After installation is finalized this summer, the SEM will be the first in the United States to offer the Zeiss In Situ Lab testing “hot” stage, allowing students and professors to investigate materials while pulling and squeezing on samples at elevated temperatures.

Atwater compares the microscope to a general practitioner rather than a specialist in the medical field.

“It does a lot of things well,” he said. “If you want to prove a chemical composition definitively, there are other ways that you would get more specific information. This is probably the one-stop shop that has more versatility than any other instrument.”

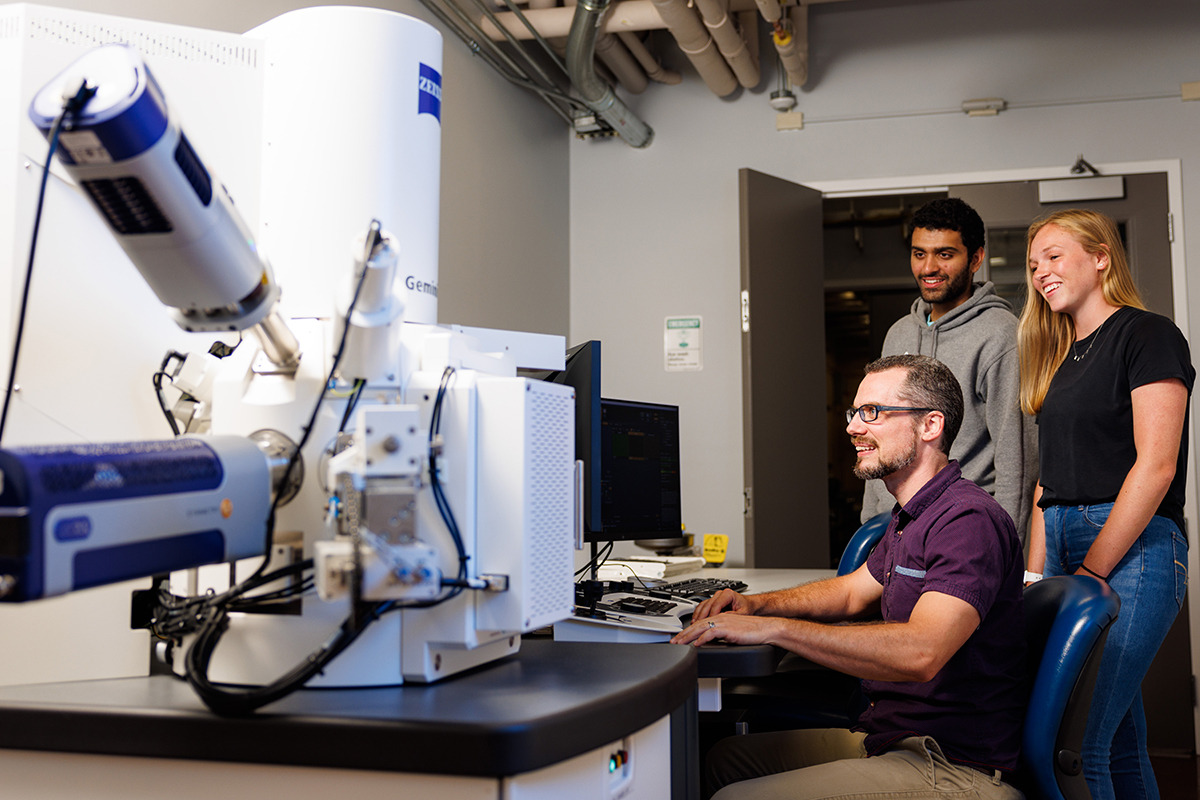

The device can also be operated remotely, with the imaging projected back to classrooms in DeMoss Hall, where LUSE is based, with the same high resolution. It will allow students to conduct more advanced research and, enable them to multitask by manufacturing samples before testing them.

“Getting students experience, rather than just the knowledge — getting them to use it and having the facilities to do that — is something that we’re really focused on,” Atwater said, noting that the automation of the Zeiss stage will make it more practical for the average user. “The specific mechanical testing capability this will have will be seamlessly integrated with the microscope to make it a lot easier to operate. You can actually set sort of a recipe and then hit start, and it will do all of the testing and collect all of the data.”

He said the data retrieved will mirror the students’ computational work as High-Performance Computing (HPC) hooked up to the microscope will help them connect what the computer analysis reveals to what is actually happening in real life. One niche of LUSE is the HPC that it conducts at both the undergraduate and graduate levels of education and research.

“Students can correlate through computer models everything that we are observing in the microscope,” Atwater said. “Then we can actually take an experiment, look at the model, and make both of them better. That’s the goal.”

Dean Mark Horstemeyer said Liberty’s dozen lab spaces at CERE are organized in a way that enable students and professors to best analyze materials for developing new alloys and testing innovative designs among numerous other applications.

“In particular here, we are focused on a material starting with its chemistry, then material processing, then we characterize its structures, look at its properties, and finally its performance environment, in that sequence,” he said.

The material processing is analyzed using 3D additive manufacturing for metals, polymers, and composites. The multiscale, heterogeneous structures of a material are then characterized using optical and scanning electron microscopes while its properties are studied using hardness testing, compression testing, and tension, high and low strain rates and temperatures, and by creating fatigue corrosion. Finally, drop towers and environmental and electromagnetic chambers located in adjacent labs are employed to evaluate the performance of a material.

Dave Fazzina, who is currently pursuing his Ph.D. in Engineering with a concentration in material science, is utilizing the SEM to analyze defects built into steels and metals. As part of his dissertation, he has mixed copper and silver together to form a metallic alloy, using the SEM to see what the dispersed phases look like.

“You create new structures by doing that, and when you remove the copper and leave the silver structure behind, it leaves a very porous, cave-like structure that has properties that are advantageous … for performing chemical reactions, like electrodes on a battery,” Fazzina said.

Mechanical engineering Professor Dr. Hector Medina is using the microscope to conduct research on titanium surfaces for bone adhesion with prosthetic implants, testing a theory on the bonding activity that occurs when it comes into contact with titanium, which happens on a scale that is undetectable without the device.

At LUCOM, Dr. Anthony Bauer, associate professor of physiology, and his medical students are using the microscope to isolate a lethal trauma protein that is released during a severe injury, such as a soldier hit by an improvised explosive device (IED) or a driver in a car crash. They are working in collaboration with Liberty’s Center for Natural Sciences and others at Walter Reed Army Institute of Research, University of Virginia, and the Mayo Clinic in Minnesota to determine the identity of the protein and develop blocking therapies to prevent the effects of trauma on the vasculature in order to save the lives of active-duty military and civilian accident patients.

Additionally, LUCOM student-doctors are using the microscope to study the cellular interactions of tumor-associated macrophages, neutrophils, and mast cells within the tumor microenvironment.