From rockets to rollercoasters, School of Engineering teams launch innovative designs for competitions

December 2, 2022 : By Ted Allen - Office of Communications & Public Engagement

A dozen competition teams led by Liberty University School of Engineering students have hit the ground running this semester with the research and development of a variety of projects — from virtual rollercoasters to rockets and concrete canoes.

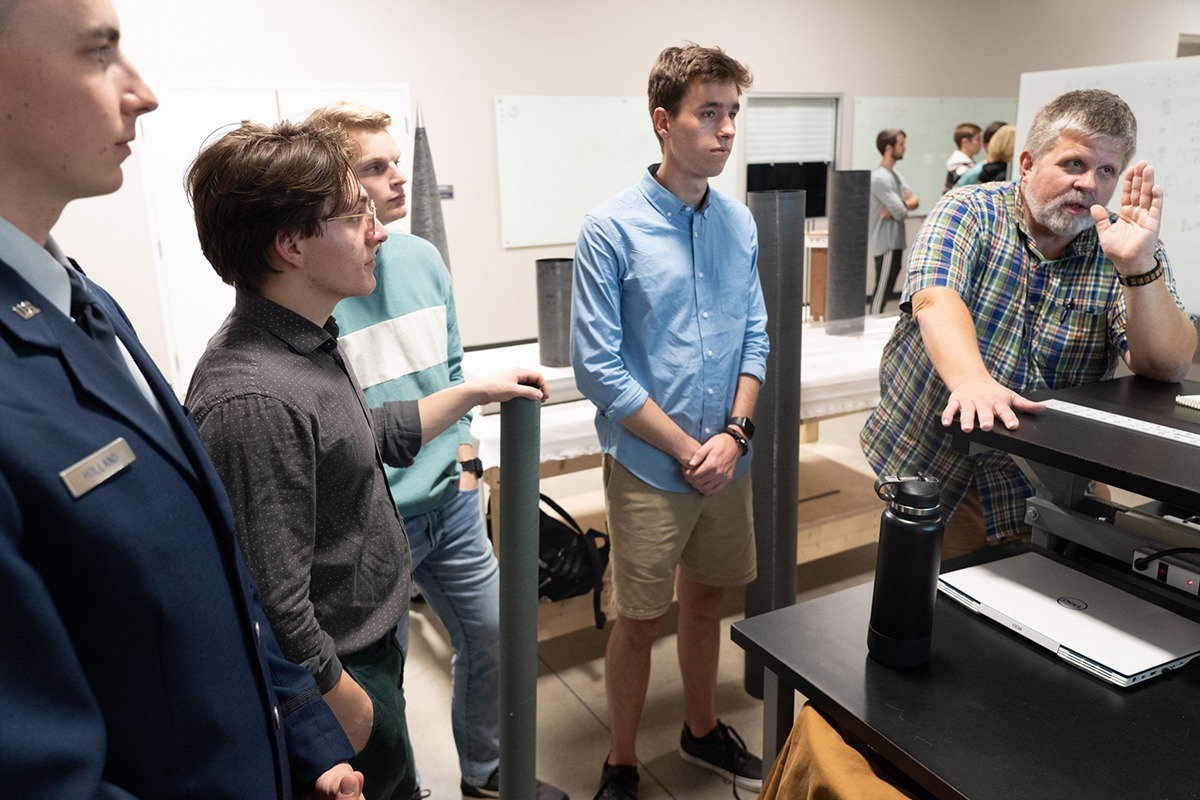

The teams are manufacturing and testing their projects in the new Hudgins Civil Engineering Building in preparation for competitions this fall through next summer. They are categorized as either mechanical, electrical, or civil engineering-based. Mechanical teams include Human-Powered Vehicle Challenge, Liberty Motorsports Baja (offroad vehicles), Formula SAE (racecars), Liberty Rocketry, and Theme Park Engineering, which was the first to compete last month.

Three new aerospace-related teams — the LU RASC-Als (a NASA-sponsored research competition on planning a mission to Mars), Liberty Orbit (space satellite design), and Liberty Aero (a Design/Build/Fly radio-controlled aircraft/small-scale drones) — were also labeled as mechanical for now.

“We started the three new aerospace-related teams because one of the things we are trying to do in the not-too-distant future is to establish an aerospace program in our department,” said Assistant Professor Dr. Tate Fonville, who supervises all the competition teams.

Daniel Hembree, a junior mechanical engineering student, is the lead project manager for the rocketry team, which he started with two other members when they were freshmen.

“We were all passionate about wanting to compete, and we were also all passionate about aerospace, and we just took it upon ourselves to create an environment where that passion could be utilized,” Hembree said. “We’re a little over two years strong, and it’s been amazing to see God grow the team and open doors for us.”

They recently received parts for their first competition rocket, Genesis, which when fully manufactured and assembled will stand over 10 feet tall. Liberty Rocketry is one of 170 international teams accepted to compete in SpacePort America, the world’s largest student competition set for June in New Mexico.

“What we’ve tried to work on this semester is defining roles and responsibilities for every sub-team,” Hembree said. “We’ve got a few from computer science, a few IT software engineering, as well as mechanical, industrial, and system engineering, and potentially a few chemists — and everyone’s engaged. What we’re trying to do here is pursue innovation and have some ambition with our design.”

Cole Derosett, the team’s chief engineer, said the Hudgins building is perfectly suited for the work.

“We have a full machine shop here, 3D printing, and a workspace to manufacture this entire rocket. This will be our first time competing, and we hope to hit 10,000 feet on the dot when we compete against world-class engineering schools.”

Virginia Tech won the competition in 2019, with a launch recorded at 10,003 feet.

RASC-ALs, which stands for Revolutionary Aerospace Systems Concepts-Academic Linkage, is a NASA- sponsored, research-based competition where students write a 40-page proposal and plan the logistics, itinerary, and survival tactics for a mission to Mars. Liberty’s team has taken a collaborative approach with input from doctors and industry experts on its board of advisors. They submitted their proposal earlier this month. Fourteen teams will be selected to present their pitches to NASA’s leads on Mars missions in Cocoa Beach, Fla., in June.

Liberty Orbit is working on a virtual design of a small-scale satellite for a virtual competition with the goal of cleaning up space junk.

“They are focused on developing satellite technology that can be low-cost, with a low-earth orbit, and that can be deployed with thousands of other satellites,” Fonville said.

Liberty Aero is designing and building a remote-controlled, small-scaled drone aircraft that can perform a set of challenges, such as carrying a package and dropping it at a certain altitude or location, or tow objects such as banners through the sky. They should be ready for competition in April 2024.

The Theme Park Engineering team sent its five members to Universal Studios in Orlando, Fla., in early November to compete in a rollercoaster design competition. Teams had to design two separate rollercoasters and Liberty’s team of president Jordan Stewart, vice president Josiah Brower, creative director Sheldon Ware, and team members AJ Jones and Quinn Reed based their design on a medieval castle theme.

“Our design had to follow all American Society of Testing and Materials (ASTM) standards for amusement park attraction design,” Stewart said.

The work required a physics engine to determine certain calculations, including whether the G forces on the rider were too much and if the track could withstand the forces. Part of the competition involved generating graphics and animations from both external and riders’ perspectives on the route.

The team submitted a design and prototype in June and were among a select number of college and university programs to travel to Florida for the final “Thrill Design” competition.

“In addition to the rendering of our design, we made a presentation including the engineering design aspects of the design and other notable features,” Stewart said. “We were given the specifications on Thursday morning and we presented our design to a jury of engineers at Universal Creative on Friday morning.”

Liberty’s designs competed with the likes of the University of Arizona, Auburn University, University of California-San Diego, Carnegie Mellon University, University of Central Florida, Drexel University, University of Florida, University of Michigan, University of Nebraska-Lincoln, Northwestern University, University of Notre Dame, Penn State University, Rochester Institute of Technology, Savannah College of Art & Design, University of Texas at Austin, and Virginia Tech among others.

The Formula SAE team will compete in May in Michigan. The competition traditionally called for building an electric racecar, but this is the first year they will be required to build a gas-powered engine. The Baja team, meanwhile, will travel to Ohio with their all-new four-wheel drive vehicle next September.

The electrical engineering-based teams are two robotics teams: Vex Robotics, which will compete in March, and Vanguard Mars Rover, which has a qualifier this fall and if their proposal is approved, will develop a prototype and submit for competition in the spring.

“If they pass that, they get invited to Utah, where NASA goes to study (the terrain of) Martian environments,” Fonville said, noting that only 30 of the more than 100 teams will be selected.

Under civil engineering, Liberty offers the Steel Bridge and Concrete Canoe teams. Both teams will travel to the same competition hosted by the American Society of Civil Engineering (ASCE) at Marshall University in Huntington, W.Va., in April.

“The Steel Bridge team has to design a deployable wildlife bridge for the Pacific Northwest that they can stand on one side of an interstate and deploy the bridge cantilever over the interstate and place it on the other side,” Fonville said. “They’re designing and building a real structure to scale and will do strength tests on the bridge, and they want it to be natural-looking.”

The Concrete Canoe team is using an especially high-performance concrete blend to manufacture a canoe that can hold two to four team members and must maneuver through a set of challenges on a lake.