Search News Archives

Filter News Articles

Additional Navigation

Young entrepreneur introduces biodegradable bags that could help environment during COVID-19 pandemic

June 9, 2020 : By By Logan Smith/Liberty University News Service

Liberty University rising senior Jose Chen had three to five minutes to pitch the idea for a new biodegradable material, and he was determined to impress. To prove its functionality, he dissolved a piece of the bag in warm water. Then he drank it.

His presentation was part of Liberty’s Spark! Incubator Program, a free yearlong training program through Liberty’s Center for Entrepreneurship under the School of Business. Students work one-on-one with professional mentors as they design and develop products to bring to market. The program culminates with the Spark! Tank event, where students pitch their ideas to a panel of judges for a chance to win cash prizes to grow their business.

“Doing the Spark! program was really good. I learned a lot on how to present my business from a different standpoint,” he said. “Also, it was good to persuade people or get them interested in my idea.”

Chen had already started to see success with Hidrobag, which factory-crafts eco-friendly T-shirt bags, grocery bags, boutique bags, and other carriers and products. Hidrobags is a company created and developed by a group of doctors and engineers in Chile. The material is made partly from cassava starch and vegetable oils, which provide fertilizer for the ground when disposed, and they even feed marine life if dissolved into lakes or oceans. And, as Chen proved by his presentation, Hidrobag products are 100 percent edible. His creative pitch catapulted him through the preliminary rounds of the competition, which took place in the spring before COVID-19 regulations prevented in-person gatherings. (The finals were canceled due to COVID-19).

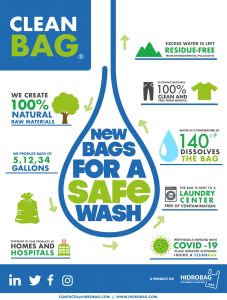

As Hidrobag learned more about the needs of people during the pandemic, his team researched ways the company could become involved. Hidrobag launched a new product called Cleanbag, a hydrosoluble laundry bag that allows workers to handle large amounts of laundry without touching any clothes. The bags, filled with clothes, can go directly into a washer. The bags dissolve during the wash cycle and leave zero residue. Bags come in 5- 12- and 34-gallon sizes.

“I believe this product is important, especially right now,” said Chen, 23. “Hidrobag really wanted to help during this pandemic. The process of laundry for hospitals is very complicated and expensive.”

“I believe this product is important, especially right now,” said Chen, 23. “Hidrobag really wanted to help during this pandemic. The process of laundry for hospitals is very complicated and expensive.”

Chen acquired experience from his father, who worked 20 years in plastic manufacturing with clients all over the Caribbean and Latin America.

“My dad gave me a lot of exposure,” said Chen, who occasionally traveled with his father on business trips. “I got a lot of experience working with him and seeing what everyone was doing.”

Born in Costa Rica to a Chinese father and Latin American mother, Chen inherited a rich cultural heritage. He grew up speaking both Spanish and English and translated documents, contracts, and meetings for his father’s company. Following high school, he moved to China for almost two years to strengthen his Chinese.

While in China, Chen applied to Liberty, originally planning to pursue engineering. But after three semesters, he switched to international businessand project management.

Hidrobag has received orders for biodegradable products from Spain, Italy, Germany, as well as from countries on the Western hemisphere. The first factory was planted a year ago in Costa Rica, and he plans to expand to different countries in South America and the United States. The new Cleanbag product has sold in Chile as well as to hospitals in Costa Rica.

His success is more than a business dream. Chen sees Hidrobag as an opportunity to supply income while helping a greater cause.

“We have a plastic island the size of Texas floating around in the ocean,” he said. “I believe it’s time to make a change in the way we handle waste. I feel like people are more environmentally conscience now, and they are willing to make the steps to implement that change.”

The decomposition period for Hidrobag products (when not immersed in water) ranges between 90-180 days, depending on moisture exposure.

Chen said the Spark! incubator program helped him sharpen his business idea and led to networking opportunities that he never thought possible.

Edward Giard, former vice president for Under Armor, noticed the innovative product and jumped on board as one of his mentors.

“When I was first introduced to Jose’s concept, I thought it was a really good idea,” Giard said. “It was almost too good to be true. … This could replace all the plastic grocery bags that are proliferating everywhere and being outlawed in several states. … I had heard of things like this, but never anything that could be made into a strong, thin film.”

As his professional mentor, Giard regularly met with him to help shape Hidrobag’s business model, implement strategies in a growing US market, and advised how to expand without losing control of his main assets.

As his professional mentor, Giard regularly met with him to help shape Hidrobag’s business model, implement strategies in a growing US market, and advised how to expand without losing control of his main assets.

“I cannot tell young men and women what to do, but I can guide them so they can avoid some of the pitfalls that I stepped in and learn from the lessons I learned,” he said.

Chen said that without Liberty’s School of Business and the Center for Entrepreneurship, he would not have garnered the same amount of connections and resources.

“Liberty has helped me a lot,” he said. “I feel like I’ve grown a lot as a person, personally and professionally, because of this school. And the incubator program really gave me a lot of experience with presenting and public speaking. …This development wouldn’t have been possible without a group of engineers and doctors from Chile.”