Search News Archives

Filter News Articles

Additional Navigation

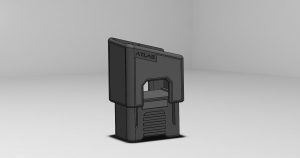

Student brings firearm loader invention to market with help from Liberty’s Center for Entrepreneurship

September 9, 2020 : By Logan Smith - Office of Communications & Public Engagement

Liberty University mechanical engineering sophomore John Coggins didn’t expect to enrich his entrepreneurial spirit while in college, but the Center for Entrepreneurship in the School of Business helped him to not only keep his dream alive, but also see it through.

Liberty University mechanical engineering sophomore John Coggins didn’t expect to enrich his entrepreneurial spirit while in college, but the Center for Entrepreneurship in the School of Business helped him to not only keep his dream alive, but also see it through.

“I’ve always wanted to start a business,” Coggins, 19, said. “When I came to Liberty, I wasn’t pursuing my idea completely, but Liberty brought my product from nothing but a prototype to selling my product in a store and selling them online.”

As a gun enthusiast with two family members in the Marine Corps, Coggins was in high school when he first had the idea to improve the reloading functionality of a Glock handgun. He said refilling a magazine, regardless of brand, becomes increasingly difficult as the magazine nears its bullet capacity.

“I just started brainstorming ideas,” he said. “I wanted to do something simple, so I thought about guns. I thought about what was wrong with guns.”

Each Glock handgun purchase includes a small plastic speed loader. Coggins said the cheap plastic — which suppresses the magazine spring from the top — is inconvenient because it breaks easily, is often lost, and doesn’t remain on the pistol while shooting.

Coggins wanted to design a stronger, more effective product that performed a similar task, but that remained latched to the magazine’s base while shooting.

“Speed loaders exist, but they hold the spring from the top,” he said. “So, I thought, ‘What would happen if you just let the spring come out the bottom?’”

Coggins’ idea was born, and he immediately went to the sketchpad. After visualizing his project on paper, Coggins purchased a cheap 3D printer and downloaded free Google software.

His first plastic prototypes successfully attached to the bottom of a Glock 19 magazine as planned. The baseplates also released the spring tension. But there was a problem.

“They were never strong enough to withstand a loaded magazine,” said Coggins, who lacked the proper industry tools to craft an efficient, strong, marketable product.

Coggins pushed his invention aside, determined to revisit his idea after earning a mechanical engineering degree. He quickly filed a provisional patent application, which secured his intellectual property for a year. Coggins named his business “Atlas Armory” and titled his magazine product “Quick-Clip.”

But when he came to Liberty, he told others about his product and soon established friendships with several senior engineering students who wanted to help him refine the Quick-Clip.

“When John first approached me, I remember expressing to him my relief and joy at the fact that someone was finally working on a solution to that problem,” said Patrick Chaverri (’20), a former mechanical engineer student at Liberty. “(With his prototype), he got some things right and some things needed tweaking. But overall, I was impressed with it and thought it was a respectable prototype coming from the not so great resources he had available to him at the time.”

Chaverri said most of the flaws in Coggins’ original design were related to the ease of operation. Sometimes parts of the Quick-Clip wouldn’t open properly or were rough to slide onto the host magazine.

“I have always loved designing, building, and fixing things,” Chaverri said. “That’s why I chose to study engineering, and that’s why I chose to help John. Another big reason why I helped John is because of my personal experience with the problem he was trying to fix.”

“Whenever I was helping him, he would often ask for my opinion on the various design changes he wanted me to make,” he added. “He didn’t just use me. He worked with me and let me work with him on his idea, and I appreciated that he chose that approach. I’m really happy that I got to contribute to an idea like the Quick-Clip and that I got to work on it with a person like John. I hope that I will be able to purchase the Quick-Clip soon so that my poor thumbs can have a more pleasant shooting experience.”

The engineering department, together with Liberty’s Center for Entrepreneurship, which aims to help students from all degree programs fashion their business concepts, helped Coggins realize the potential.

Through the center, Coggins was connected with former Vice President of Under Armor Edward Giard, who helped Coggins license and manufacture his product.

“John is a good kid,” Giard said. “He’s young, confident, and full of ideas. He is eager to learn and willing to listen. I’ve been impressed with what I have seen. He’ll go places.”

Coggins is currently preparing to sell his product on his website, and he even has units for sale in a gun store in southern Virginia.

“Without Liberty, I would have put it off until I graduated, but this university — especially the Center for Entrepreneurship and the School of Business — definitely helped me.”

His products are made in San Francisco with multi-jet fusion, an advanced 3D printing method that laser-heats layers of plastic powder into stronger, more concise molds.

“I went from a cheap, poorly designed model, and now I get them made with multi-jet fusion which is 12 times stronger than a typical 3D printer,” Coggins said.

His goal is to sell 1,000 units by 2021 and have the product available in 10 stores. He wants to contribute his proceeds to fight against human trafficking.

“Human trafficking targets individuals who cannot defend themselves. …” he said. “I want to at least raise awareness that the issue is very prominent in America, especially big cities like Atlanta, Georgia. Hopefully Atlas Armory can work up to that point where we can make a real change and impact on the corrupt business of human trafficking in the United States.”

Coggins’ long-term mission complements the Center for Entrepreneurship’s ultimate goal: to implement a strong biblical worldview so that young business owners who benefit from the center can further God’s kingdom and change the world for the better.